Plastics

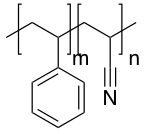

Styrene acrylonitrile (SAN)

General information

Description

Styrene acrylonitrile (SAN) belongs to the Styrene family and has similar properties as ABS. It is very rigid and has a high impact strength. Contrary to ABS it can be produced as transparent material. It can have a high gloss. It is not particularly inexpensive and often used for quality products.History

SAN was first patented in 1938. It has been commercially available since the 1940s. It was succeeded in the 1950s by ABS.Production, Application, Appearance

SAN is resistant to fats and oils and to cleaning agents and is dishwasher proof. Therefore, it is used for the manufacture of domestic products, automotive industry, and electrical appliances.Properties

Material properties

ThermoplasticDensity: 1.07-1.09 g/cm3

Melting point: 106°C

Glass transition temperature: 103-112°C

Identification properties

Cell structure (foam): not applicableSmell: no characteristic smell

Touch: no characteristic touch

Sound: can make a tinny sound

UV-radiation (when clear): fluoresces blue clearly

Polarizing filters (for clear PS): not applicable

Degradation

Process

Photo-oxidation.Details

SAN is not considered a problem plastic.Symptoms

Discolouration, loss of mechanical properties resulting in tears and fractures, material becomes brittle.Susceptibility

UV-radiation: MediumLight: Medium

Oxygen/Ozone: Low

Temp: High - becomes brittle below 0°C

RH: Medium

Preventive conservation

Recommendations

UV-RADIATION: keep below 75 µW/lm UV filter for daylight and fluorescent light - reduce intensityLIGHT: 1 slight change in approx. 30 Mlx.h Moderate light dose - control intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: Do not keep below 0°C

RH: common museum conditions 40-60% RH fluctuations: setpoint ±10% or ±5% when allowing seasonal fluctations between 35-65%