Plastics

Plasticized Polyvinyl chloride (PVC - P)

General information

Description

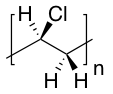

Plasticized polyvinyl chloride (PVC-P) is one of the most used and cheapest plastics. The addition of plasticizers makes the material soft and flexible. These plasticizers cause a smell that is described in the PIT as shower curtain or swimming armbands (inflatables). PVC-P is available from clear, transparent to opaque. It produces a dull sound when tapped upon. The surface can be scratched. Aged P-PVC can feel tacky and the material can discolour significantly. As the plasticizer migrates and disappears, the material becomes hard and rigid.History

PVC was a difficult material to process until the method to plasticize PVC was developed in 1928. Commercial production started in the 1930s and during World War II is was used as a substitute of natural rubber. In 1952 is was first used to make flexible dolls. Mid 1960s transparent PVC-P film was introduced which enabled manufacture of inflatable objects.Production, Application, Appearance

PVC-P is used for a wide range of products, such as shower curtains, water shoes and boots, inflatable objects, toys, transparent film, document sleeves, electricity wire, and tubing. It is also used as a coating, for instance to produce imitation leather.Properties

Material properties

ThermoplasticDensity: 1.37-1.43 g/cm3

Melting point: 103-230°C

Glass transition temperature: 66°C (5 phr plasticiser); 13-52°C (30 phr plasticiser); -52 to -82°C (100 phr plasticiser)

Identification properties

Cell structure (foam): closedSmell: swimming armbands / shower curtain

Touch: no characteristic touch

Sound: dull

UV-radiation (when clear): fluoresces clearly blue or yellow

Polarizing filters (for clear): does not produces a colour pattern; film can look somewhat brownish and white / greyish

Degradation

Process

Degradation of P-PVC involves migration of the plasticizer to the surface (leaching) which causes a change in mechanical properties such as loss of softness and flexibility. Loss of specific plasticizers may also increase the materials susceptibility to ageing. Contact between P-PVC and packaging material appears to increase migration of plasticizer, as does absorbing of venting it. Photo-oxidation of the polymer.Details

PVC-P is considered a problem plastic due to the migration and leaching of plasticizers.Symptoms

Discolouration, surface becomes tacky, white bloom or liquid on the surface, shrinking, deformation, hardening.Susceptibility

UV-radiation: HighLight: High

Oxygen/Ozone: Low

Temp: Medium (migration of plasticizer)

RH: Medium (fluctuations)

Preventive conservation

Recommendations

UV-RADIATION: keep below 10 µW/lm Exclude UV with filters or no-UV light sourceLIGHT: 1 just noticeable change in approx. 1 Mlx.h Limit light dose by reducing intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: common museum conditions 15-25°C. The cooler the slower the migration of plasticizer will take place

RH: common indoor conditions 30-70% RH fluctuations: setpoint ±5%

—

PVC-P might be stored in a non-absorbing material such as glass or polyester. Degraded PVC-P can affect metal / paper / ink / textile and PS - therefore - separate storage is recommended.

Other names

- PolyOne

- Darvic

Am I dealing with...

TAGS

- Closed cell structure

- Sticky

- Skin