Plastics

Soft Polyurethane ester (PUR ester soft)

General information

Description

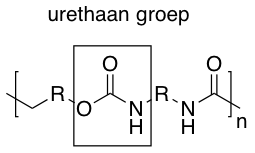

Polyurethanes come in various types and forms. Best known and most produced is PUR foam. Soft PUR foam exists in an ester and an ether variety. Their degradation differs; esters become tacky and lose their flexibility, ethers will crumble after some time.History

The first polyurethanes were developed in 1937. Around 1954 commercial production of soft PUR foam started.Production, Application, Appearance

In the factory soft PUR foam is produced as sheets or blocks. Artists can make their own soft PUR foam by mixing the two components with a blowing agent. In the past soft PUR ester foam was used a lot. When the problems with its durability came to light, it was replaced by soft PUR ether foam. It is used for particular applications such as sound insulation.Properties

Material properties

ThermosetDensity: 1.1-1.25 g/cm3; foam: ~0.011 g/cm3

Melting point: 141-157°C

Glass transition temperature: -60 to -19°C

Identification properties

Cell structure (foam): openSmell: can have a sweet chemical smell

Touch: no characteristic touch

Sound: no characteristic sound

UV-radiation (when clear): not applicable

Polarizing filters (when clear): not applicable

Degradation

Process

Soft PUR esters undergo mainly hydrolysis.Details

PUR is considered a problem plastic. The soft foams, in particular, can degrade rapidly and cause problems. Due to the open cell structure degradation occurs not only on the surface but in the core as well. A protective layer applied to the surface can slow down degradation to some extent.Symptoms

Discolouration; loss of mechanical properties such as elasticity and collapse of structure; surface becomes tacky; crumbling.Susceptibility

UV-radiation: MediumLight: Medium

Oxygen/Ozone: Low

Temp: Low

RH: High (setpoint)

Preventive conservation

Recommendations

UV-RADIATION: keep below 75 µW/lm UV filter for daylight and fluorescent light - reduce intensityLIGHT: 1 slight change in approx. 30 Mlx.h Moderate light dose - control intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: common indoor conditions 10-30°C; a lower temperature will slow down hydrolysis

RH: 10-30% RH fluctuations: within bandwidth

Other names

- PU foam

Am I dealing with...

TAGS

- Sticky

- Crumbly

- Skin

- Open cell structure

- Memory Foam