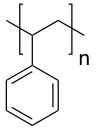

Plastics

Expanded Polystyrene (PS, EPS expanded)

General information

Description

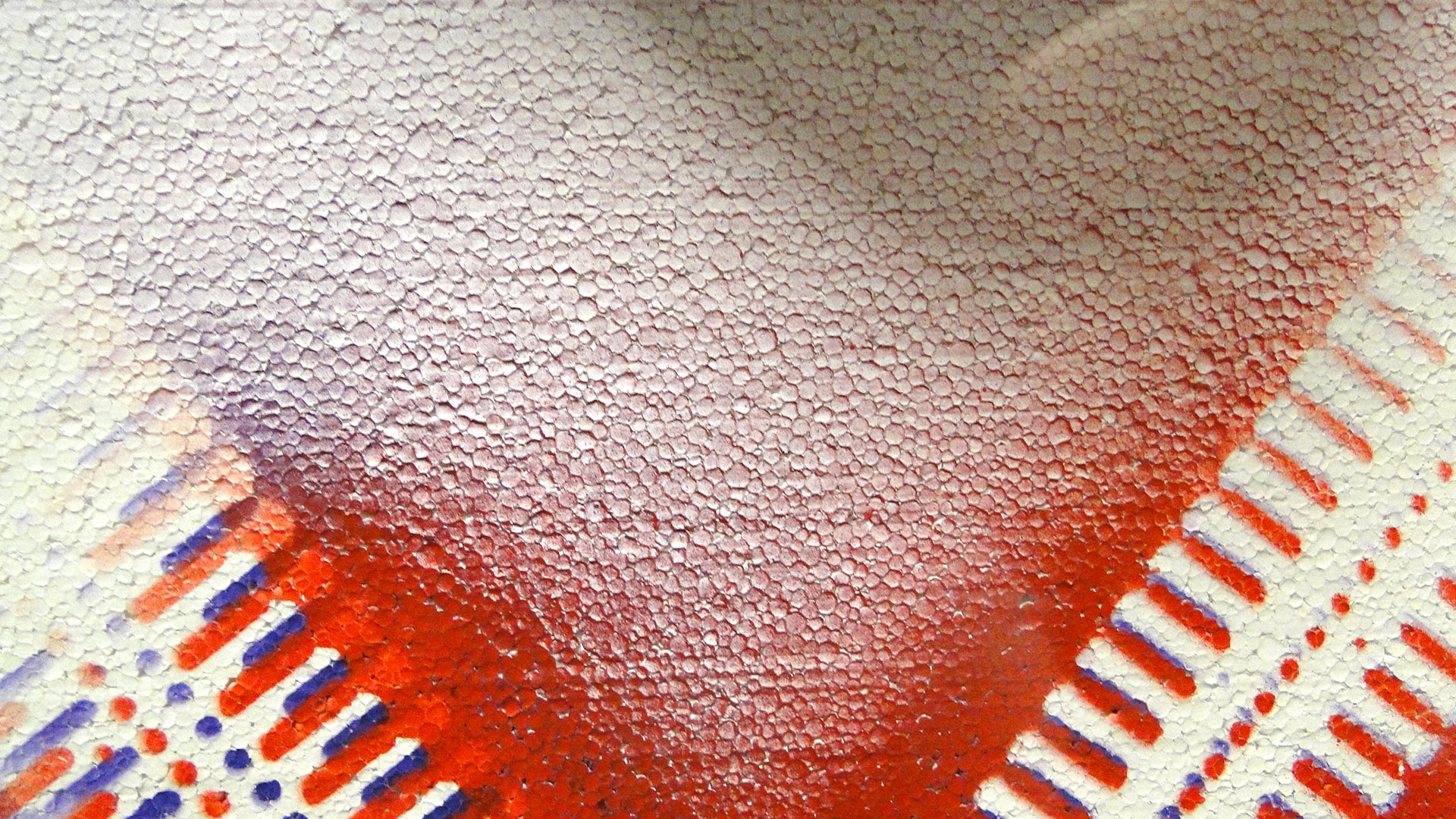

Expanded Polystyrene (EPS) is only produced as foam. It comes in sheets or blocks. It is usually white and can be recognized by its typical spherical structure. EPS makes a squeaky sound upon rubbing the surface. It is a rather hard and tough, light-weight foam. It is very susceptible to solvents, acetone will burn right through. Heat has a similar effect. Sample S-01 in the PIT-kit is an example of EPS foam.History

EPS is commercially available since 1949.Production, Application, Appearance

EPS is often sold as white panels. It is commonly used for building insulation, packing material, food containers, foam cups, packing 'peanut', and in bicycle helmets and surfboards.Properties

Material properties

ThermoplasticDensity: foam = 0.015-0.040 g/cm3

Melting point: 275°C

Glass transition temperature: 85-102°C

Identification properties

Cell structure (foam): closed - sphericalSmell: no characteristic smell

Touch: no characteristic touch

Sound: foam = squeaky

UV-radiation (when clear): not applicable

Polarizing filters (for clear PS): not applicable

Degradation

Process

Photo-oxidation; soiling (electrostatic).Details

EPS is not considered a problem plastic.Symptoms

Yellowing, surface turns matte, loss of mechanical properties resulting in tears and fractures.Susceptibility

UV-radiation: MediumLight: Medium

Oxygen/Ozone: Low

Temp: Low

RH: Medium

EPS is highly susceptible to polar and non-polar solvents, especially acetone; also for plasticizers that can be emitted by other plastics.

Preventive conservation

Recommendations

UV-RADIATION: keep below 75 µW/lm UV filter for daylight and fluorescent light - reduce intensityLIGHT: 1 slight change in approx. 30 Mlx.h Moderate light dose - control intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: common indoor conditions 10-30°C

RH: common museum conditions 40-60% RH fluctuations: setpoint ±10% or ±5% when allowing seasonal fluctations between 35-65%

—

Handle with care. EPS is not elastic and indentations are irreversible

Other names

- Polystyrol

- Styropor

- piepschuim

Am I dealing with...

TAGS

- Closed cell structure

- Skin

- Hard

- Ball structure

- Styrofoam, Tempex

- Squeaking sound