Plastics

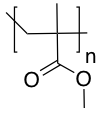

Poly(methyl methacrylate) (PMMA)

General information

Description

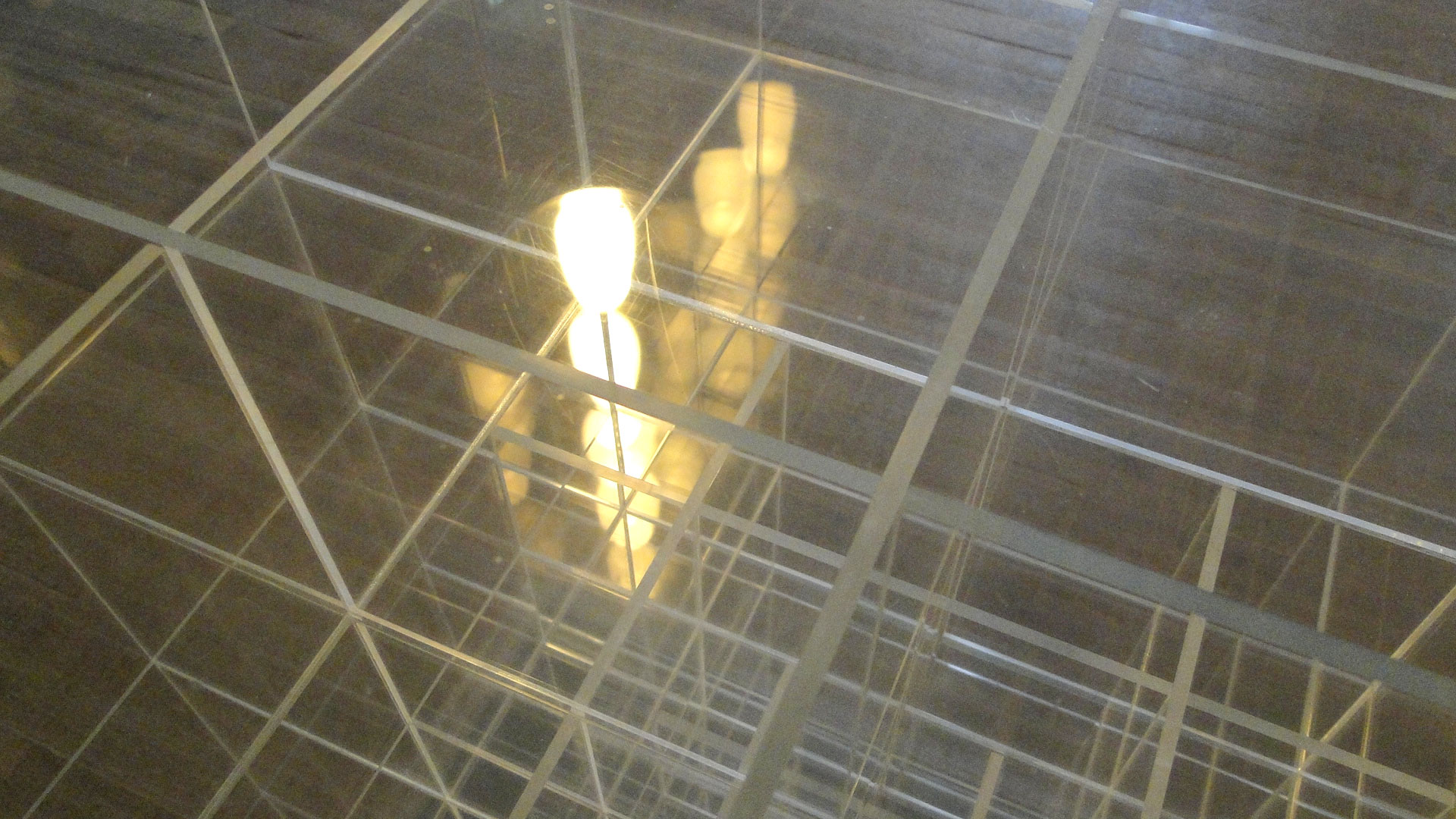

Poly(methyl methacrylate) (PMMA) is a clear transparent thermoplastic which is often used in sheet form as a light-weight alternative to glass. PMMA can be produced in different colours, translucent and opaque. The surface can be polished to obtain a high gloss. However, it scratches easily.History

The polymerisation reaction of methyl methacrylate was discovered in 1877. In 1933 the polymer was patented and registered in Germany as Plexiglas. At about the same time it was registered in England under the tradename Perspex while in the US it appeared under the trademark Lucite. In 1936 commercial production of acrylic safety glass started.Production, Application, Appearance

PMMA is processed in different ways. It is well known as sheet but can also be cast in a mould or used for injection-moulding. Sometimes calcium carbonate or fibreglass are added to PMMA. Apart from being a substitute for glass, PMMA is used in jewellery, fashion accessories, furniture, kitchen utensils, and other design items.Properties

Material properties

ThermoplasticDensity: Rigid = 1.17-1.20 g/cm3

Melting point: 105-160°C

Glass transition temperature: calc.=82-105°C; exp.=104-105°C; atactic=105-122°C; isotactic=51-107°C; syndiotactic=105-120°C

Identification properties

Cell structure (foam): not applicableSmell: no characteritic smell

Touch: no characteristic touch

Sound: Rigid = no characteristic sound

UV-radiation (when clear): does not fluoresce. Sometimes faint

blueish fluorescence

Polarizing filters (for clear CE): does not produce a colour pattern

Degradation

Process

Photo-oxidation: random splitting of polymer chain which may be accompanied by emission of gases such as methane, hydrogen gas, carbon monoxide and dioxide, methyl formate, methyl methacrylate, and methanol. PMMA is hygroscopic, absorbs and desorbs moisture which can cause crazing.Details

NoneSymptoms

Surface becomes matte, decrease of transparancy (milky clouds). A typical degradation phenomenon for PMMA is the formation of small cracks and fractures on or below the surface (crazing).Susceptibility

UV-radiation: LowLight: Low

Oxygen/Ozone: Low

Temp: High - becomes brittle at low temperatures

RH: High - crazes with fluctuating RH

PMMA is sensitive to solvents.

Preventive conservation

Recommendations

UV-RADIATION: avoid extremesLIGHT: 1 slight change in approx. 300 Mlx.h Avoid high light dose

OXYGEN / OZONE: ambient conditions

TEMP: do not keep below 0°C

RH: setpoint 30-70% RH fluctuations: keep constant - setpoint ±5%

Other names

- Perspex

- Plexiglas

- Acrylate

- Acryl

- Lucite

- Acrylite