Plastics

Polyethylene (PE)

General information

Description

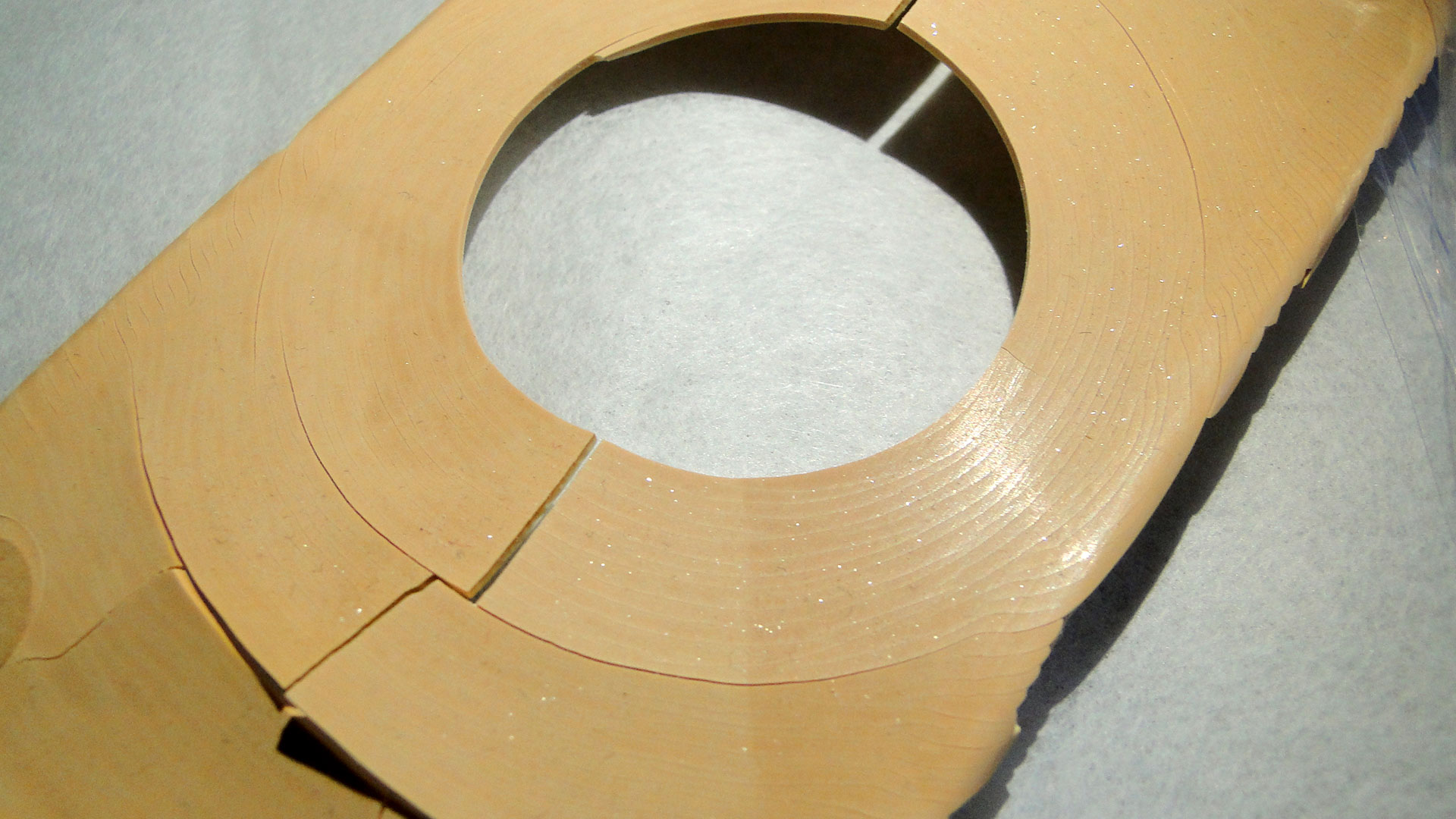

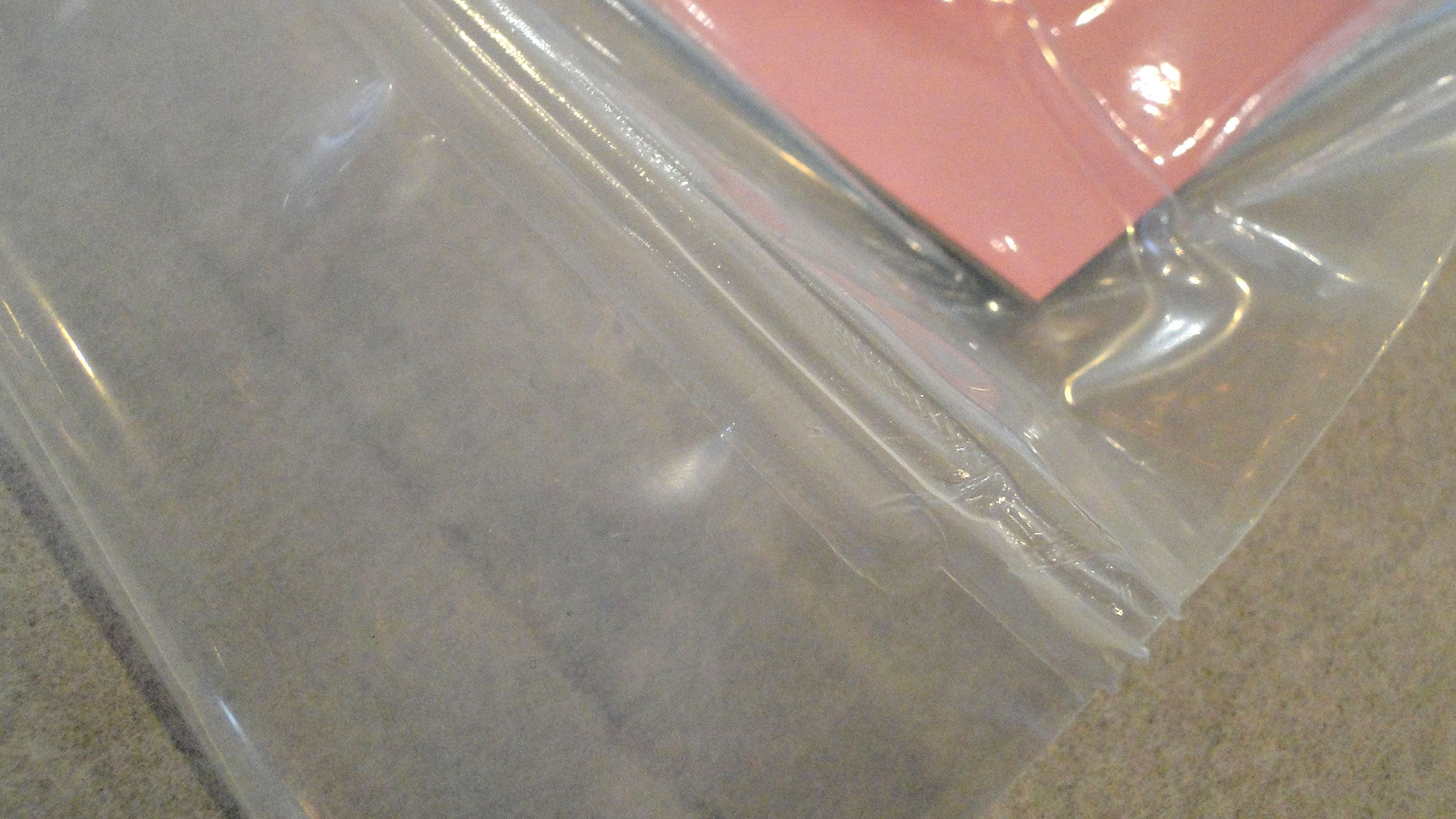

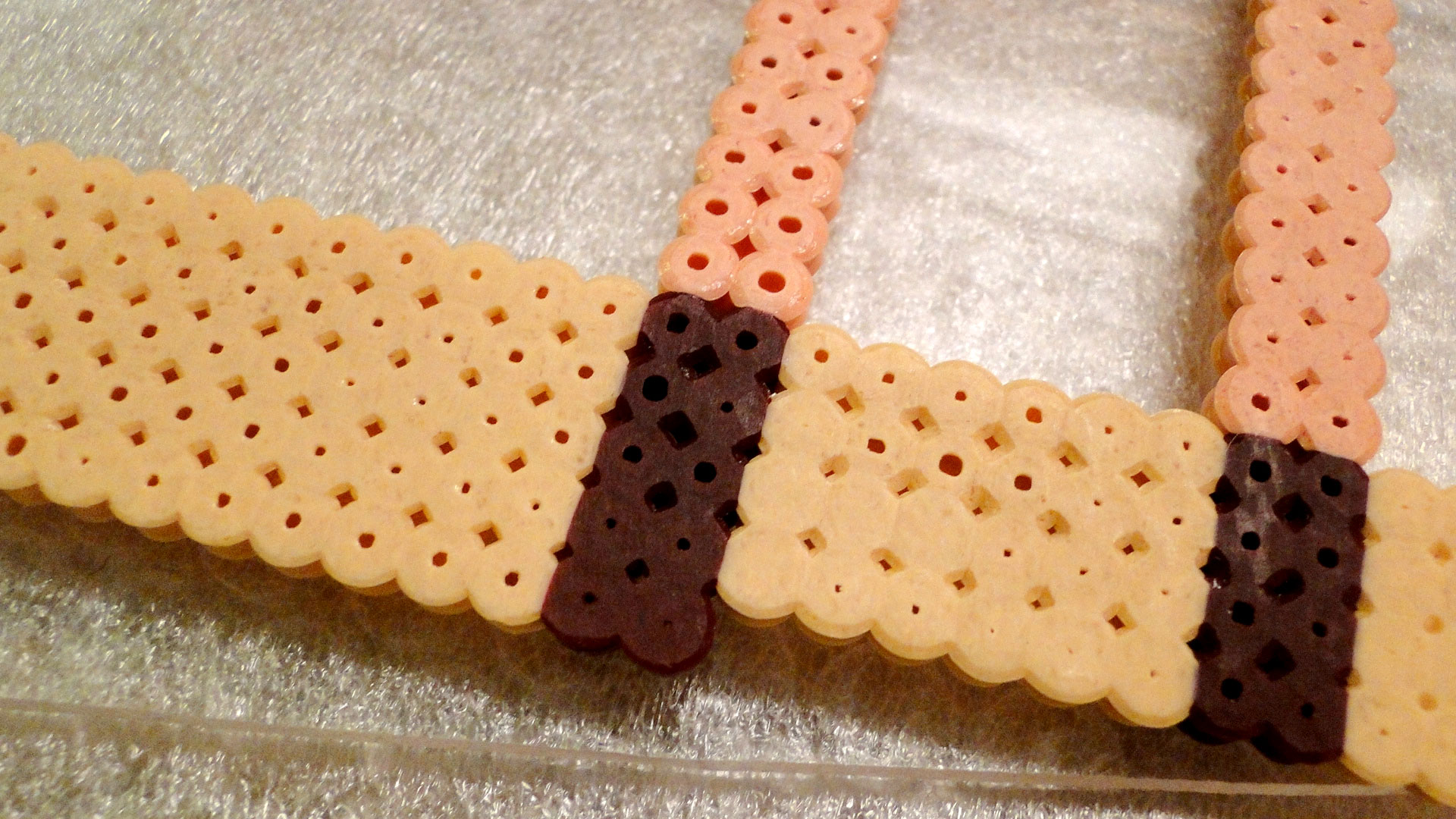

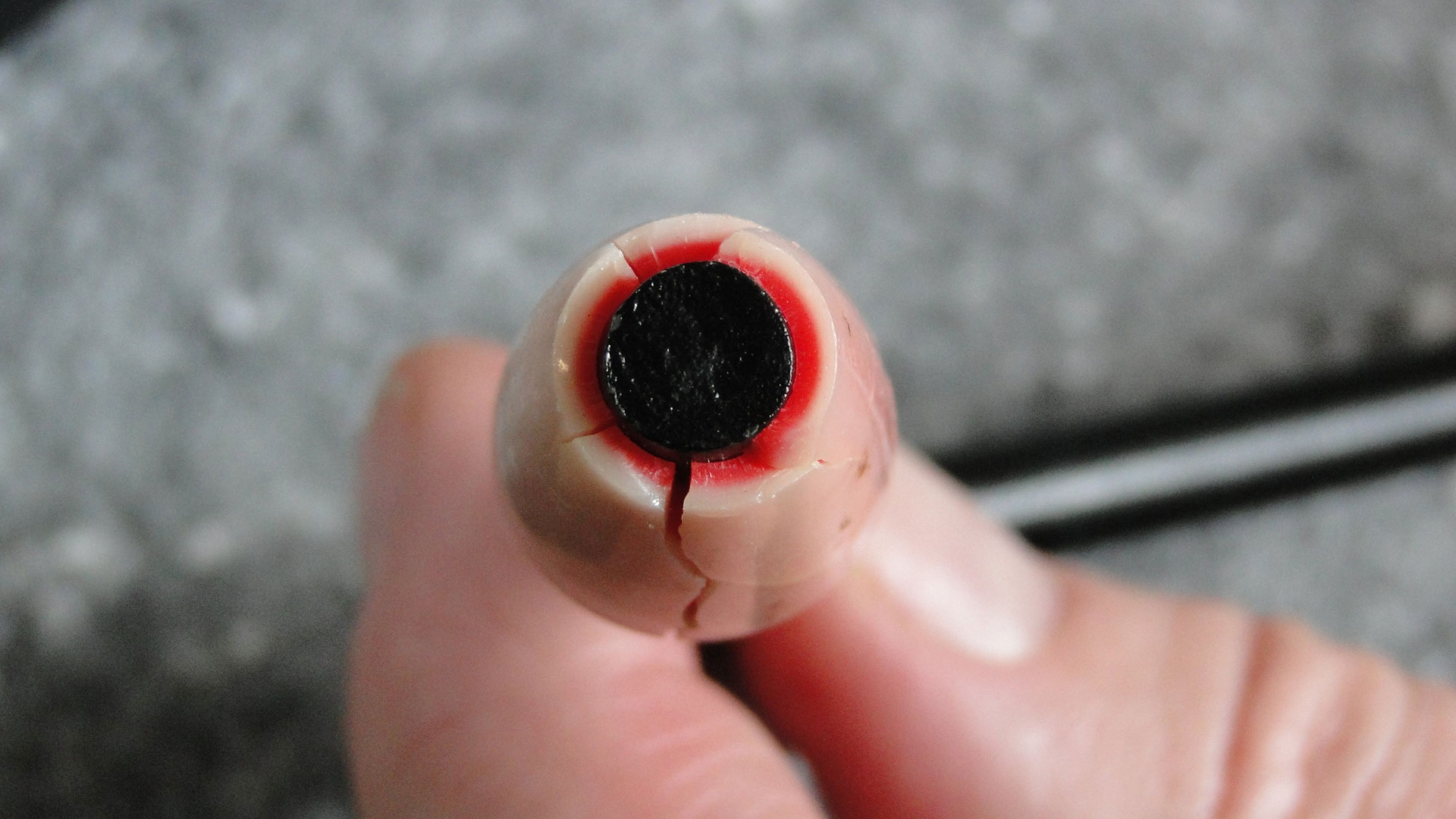

Polyethylene (or polythene, PE) is one of the cheapest plastics and the most common. It is a thermoplastic, relatively soft and flexible with a white milky colour. It comes in many forms and colours, from transparent to opaque. PE can be recognized by the waxy feel when rubbing it. Aged PE can produce a rancid, acidic smell which is described as 'old Tupperware' or 'old plastic bags' in this tool. PE makes a dull sound when tapped upon. It is difficult to print or paint on PE as the medium does not adhere to the surface well.History

Polyethylene was first synthesized in 1898 but the first industrial synthesis was developed in 1933. The first PE factory opened in 1937. There are various types of PE, the best known are LDPE (low density) and HDPE (high density). The HDPE does not have any branches in its polymer chain side chains which makes it somewhat more rigid and stiff than LDPE. LDPE is commercially available since 1939, HDPE since 1951. From 1957 onwards the commercial use of PE is extensive, also as shrink wrap. The first PE foams became commercially available after 1950.Production, Application, Appearance

There are many forms of PE and because it is an inexpensive material it is used for almost everything. It is a relatively soft and flexible material, it can be coloured and injected into moulds. PE is also produced as sheet, film, and various types of foam. It is used widely in the packaging industry, as shrink film, and for the manufacture of everyday products like bottles, (Tupperware) containers, garbage bins, toys and furniture.Properties

Material properties

ThermoplastDensity: 0.9-0.98 g/cm3; foam: 0.015-0.2 g/cm3

Melting point: 99-138°C

Glass transition temperature: -59 to -133°C

Identification properties

Cell structure (foam): closedSmell: old Tupperware or old plastic bags

Touch: waxy

Sound: Rigid = dull; foam = no characteristic sound; film = no characteristic sound

UV-radiation (when clear): does not fluoresce

Polarizing filters (for clear EVA): produces a grey / brown / whitish pattern

Degradation

Process

Photo-oxidation.Details

PE is not considered a problem plastic.Symptoms

Discolouration, surface turns matte, loss of mechanical properties resulting in tears and fractures, dimensional changes.Susceptibility

UV-radiation: HighLight: Medium

Oxygen/Ozone: Medium

Temp: Low

RH: Low

Preventive conservation

Recommendations

UV-RADIATION: keep below 10 µW/lm Exclude UV with filters or no-UV light sourceLIGHT: 1 just noticeable change in approx. 30 Mlx.h Moderate light dose - control intensity and exposure time

OXYGEN / OZONE: lower temperature slows down oxidation

TEMP: common indoor conditions 10-30°C

RH: common indoor conditions 30-70% RH fluctuations: setpoint ±20%

Other names

- Petrothene

- Formolene

- Sclair

- Ethafoam

- Tyvec