Plastics

Natural rubber (NR)

General information

Description

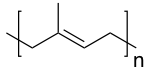

Natural rubber (NR) is harvested from rubber trees as a sticky, white fluid: latex. This latex is refined into rubber which is naturely light brown in colour and is somewhat translucent. Addition of colourants and fillers turn it into an opaque material. Often natural rubber and latex have a typical smell of sneakers or balloons. Rubber is elastic. A vulcanisation process makes the elasticity disappear and turns it into a hard material (see information page HVR). Rubber also exists as foam.History

Natural rubber is the oldest plastic we know. It is a natural polymer that was already used by the indigenous cultures of Mesoamerica and the Mayas and Aztecs used it to make balls. Mid eighteenth century it was introduced in Europe, amongst other to rub pencil from paper. Combination of latex with other components proofed to yield useful materials and in 1839 Goodyear developed the vulcanisation process to harden rubber.Production, Application, Appearance

After harvesting the latex from the tree it is processed in various ways. Additives can change properties such as elasticity. This can also affect the ageing behaviour of the material. Nowadays it is possible to synthesize natural rubber (see information page SR). Natural rubber is used in balloons, shoe soles, gloves and rubber bands. Artists can shape latex in moulds to produce their own objects.Properties

Material properties

ElastomerDensity: 0.906-0.95 g/l; foam: ~0.40 g/l

Melting point: 30-35.5°C

Glass transition temperature: -75°C (natural rubber); -70 to -72°C (polyisoprene)

Identification properties

Cell structure (foam): closedSmell: sneakers / balloons

Touch: no characteristic touch

Sound: no characteristic sound

UV-radiation (when clear): fluoresces yellowish

Polarizing filters (when clear): does not produce a colour pattern

Degradation

Process

Photo-oxidation, oxidation by ambient oxygen and ozone, soiling (tacky surface), absorption/desorption of moisture (?), depolymerisation catalysed by metals. Sulphur containing vapours from rubber may tarnish silver.Details

NR is considered a problem plastic due to its high susceptibility to oxidation.Symptoms

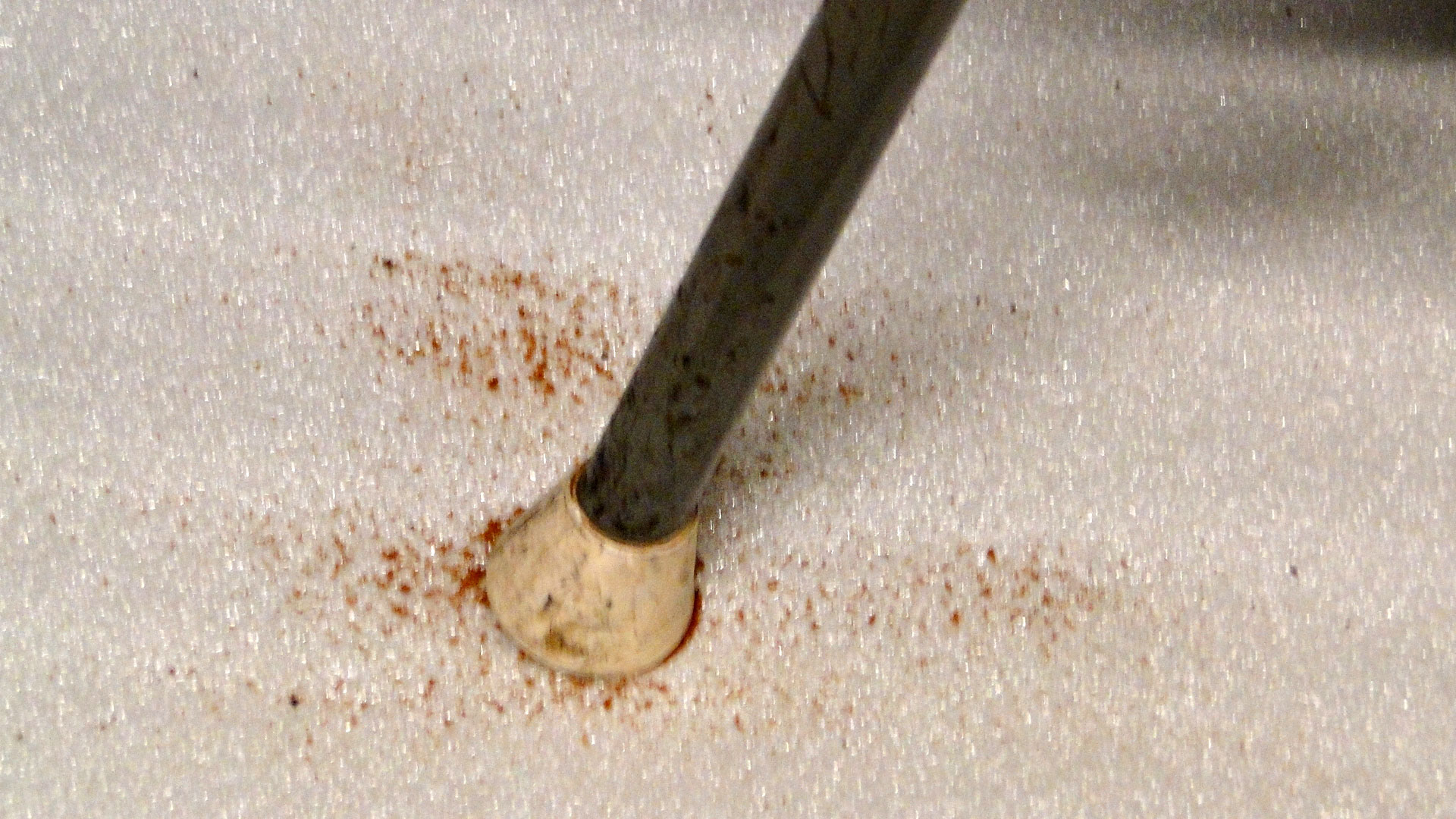

Discolouration; surface becomes tacky followed by the material becoming harder and more brittle; loss of mechanical properties such as flexibility and deformation; formation of fractures, cracks and tears; migration of additives which can form a white bloom on the surface. Foams can discolour, harden, and ultimately crumble.Susceptibility

UV-radiation: HighLight: High

Oxygen/Ozone: High

Temp: Medium

RH: Highly sensitive to fluctuations

Preventive conservation

Recommendations

UV-RADIATION: keep below 10 µW/lm Exclude UV with filters or no-UV light sourceLIGHT: 1 slight change in approx. 1 Mlx.h Limit light dose by reducing intensity and exposure time

OXYGEN / OZONE: store and exhibit in low oxygen atmosphere if possible

TEMP: common museum conditions 15-25°C; lower temperatures slow down chemical reactions

RH: common museum conditions 40-60% RH fluctuations: keep constant / setpoint ±5%

—

Note: Because the surface gets tacky - store in a clean environment - avoid soiling. If possible do not store rubber in contact with metals; copper and manganese catalyse depolymerisation of rubber while sulphur emitted from rubber may tarnish silver.

Other names

- Natural isoprene rubber

- Pararubber

- Latex

Am I dealing with...

TAGS

- Closed cell structure

- Hard (due to degradation)

- Foam rubber

- Hard and sandy

- Sticky

- Crumbly

- Elephant skin

- Skin

- Rubbery odor