Plastics

Polyamide (PA)

General information

Description

There are many different polyamides with different components linked by amide bonds. The best known non-aromatic polyamides are the nylons. Examples of aromatic polyamides (aramids) are Kevlar and Nomex. PA is milky white by nature and reflects UV radiation strongly. Thin PA film can be colourless and transparent. As the film gets thicker it will at best be translucent. Pricewise PA is mid-range, not very expensive, not very cheap.History

The first patent for polyamide dates from 1931. In the following years a variety of PA products became commercially available, such as women's stockings and men's shirts made of nylon fibre. During World War II parachute cloth and cords were made of PA fibre. From 1941 onwards PA was processed by casting and moulding, especially for military purposes. After World War II civil applications of cast PA were sold.Production, Application, Appearance

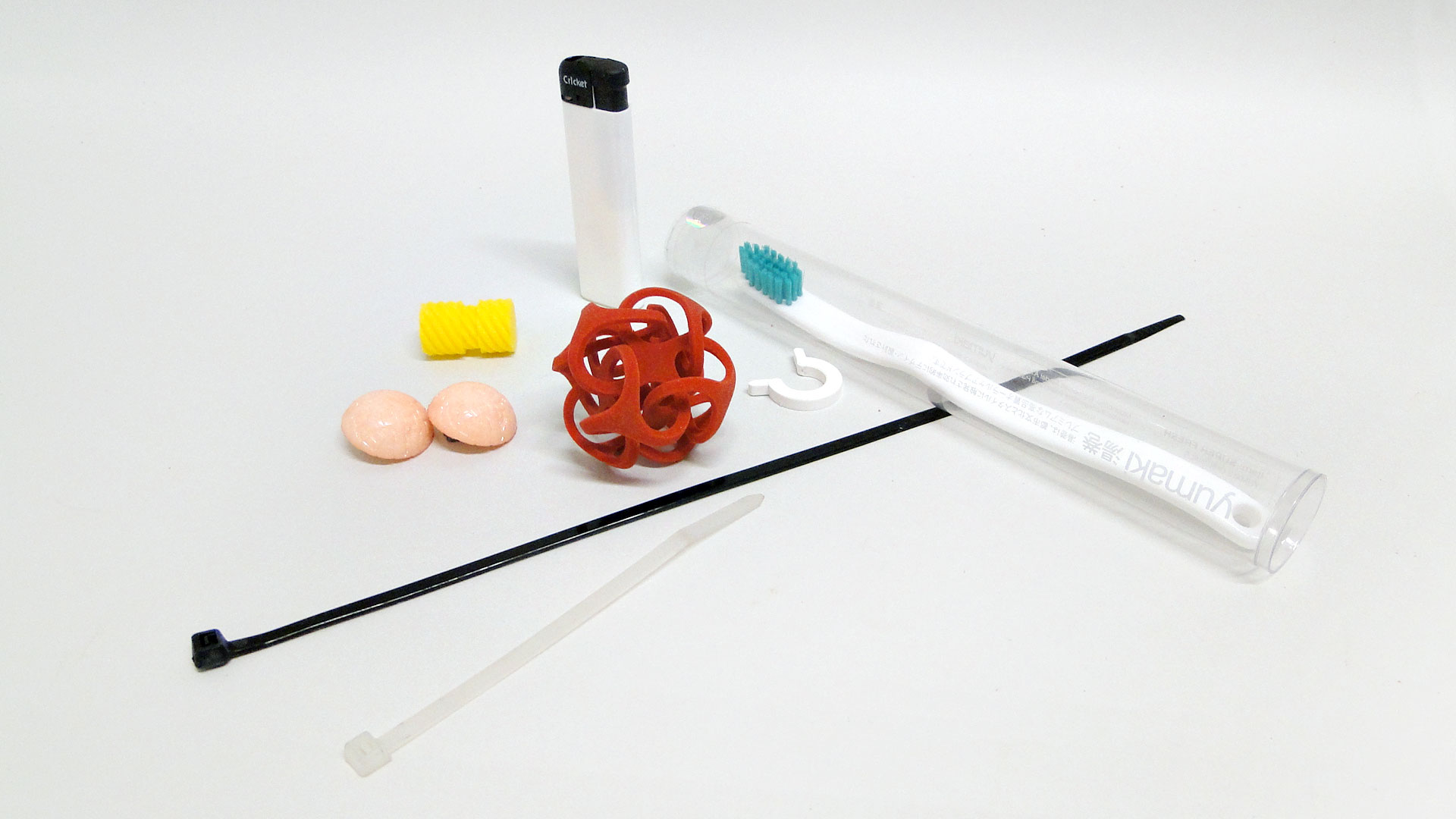

PA is best known as nylon, used as fibre in fabrics, fishing line, and toothbrush bristles. PA can also be produced as film and sheet and can be cast or injection-moulded into shape. It is used for ski bindings, cable tie (Ty-Rap), spectacles and cigarette lighters. Due to their high strength, stiffness and durability polyamides are also used as a substitute for metal (e.g. aluminium). They have a high resistance to abrasion and high mechanical and impact strength. Nowadays PA is often used in 3D-printing.Properties

Material properties

ThermoplasticDensity: 1.03-1.33 g/cm3

Melting point: 176-330°C

Glass transition temperature: ??°C

Identification properties

Cell structure (foam): not applicableSmell: no characteritic smell

Touch: no characteristic touch

Sound: Rigid = dull; film = no characteristic sound

UV-radiation (when clear): fluoresces blue clearly

Polarizing filters (for clear CE): does not produce a (colour) pattern

Degradation

Process

Polyamides are hygroscopic, they expand and shrink upon absorption and desorption of moisture. PA will not show stress-fractures rapidly. Titanium dioxide, added as piment, accelerates photo-oxidation. Especially PA fibres are sensitive to this process.Details

Is not considered a problem plastic.Symptoms

Yellowing, cracks, fractures.Susceptibility

UV-radiation: MediumLight: Medium

Oxygen/Ozone: Low

Temp: Low

RH: High

Preventive conservation

Recommendations

UV-RADIATION: keep below 75 µW/lm UV filter for daylight and fluorescent light - reduce intensityLIGHT: 1 just noticeable change in approx. 30 Mlx.h Moderate light dose - control intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: common indoor conditions 10-30°C

RH: setpoint 60% RH fluctuations: keep constant - setpoint ±5%

Without additional stabilisers PA is not suited for outdoor use.

Other names

- Nylon

- Dartek

- Kevlar

- Carbamide

- CoolPoly

- Stanyl

- EcoPaXX

- Ultramid

- Aculon

- Akulon

- Grilon

- Zytel

- Grilamid

- Rilsan B